Towards a Greener Future in Sri Lankan Export Agriculture

With the progress gained by humans in their civilization, many important landmark achievements were made and all these contributed for humans to become the dominant species on this earth. However, with the beginning of industrial revolution which was one of the turning points of human history, some adverse impacts of development also came into existence with the addition of unfavorable material to the environment by humans. Human-induced climate change due to increased greenhouse gas (GHG) emissions is one of such issues which have become one of the most severe and challenging environmental issues existing globally at the moment. There are a number of contributory factors for anthropogenic climate change and agriculture and agriculture-based industries are prominent causes among them.

Since the past, Sri Lanka has been an agricultural nation and during the colonial period, several crops with commercial value were introduced to Sri Lanka. Among these, Tea (Camellia sinensis) and Rubber (Hevea brasiliensis) are the main two export crops that bring a significant foreign income to Sri Lanka even at the present. Due to their commercial value, both Tea and Rubber are being cultivated at a larger scale. However, due to use of energy sources like fossil fuels and electricity within the industries associated with these cultivations, a considerable amount of GHGs are released to the environment. As now, the world is marching towards more sustainable consumption levels, it has become important to mitigate these GHG emissions to gain proper recognition in the global market. Therefore, with the aim of quantifying the GHG emissions associated with the energy usage in Tea and Rubber industry sectors of Sri Lanka and identifying measures to reduce the GHG emissions, a study has been conducted by Dr. Jagathdeva Vidanagama for his PhD research at the Department of Zoology and Environment Sciences of University of Colombo under the supervision of Prof Erandathie Lokupitiya.

Prof. Erandathie Lokupitiya

Department of Zoology and

Environment Sciences, Faculty of Science

Dr. Jagathdeva Vidanagama

Department of Zoology and

Environment Sciences, Faculty of Science

In this study, Dr. Vidanagama has used the Product Life Cycle Assessment (LCA) methodology to quantify the GHGs emitted from these two industries. LCA can be considered as one of the best approaches to evaluate the environmental impact of products. Here, the impact towards the environment can be defined as mid-point and end-point impacts of products’ life cycle . In this study, cradle-to-gate emissions (i.e. the GHG emissions considered starting from the plantations up to the final processing in factories) were considered.

Sri Lanka has gained a huge recognition for tea production and it has been sold worldwide under the popular trade name of “Ceylon Tea” for a long time. In Sri Lanka, tea is cultivated in 14 districts and the tea estates are controlled by state plantation companies, regional plantation companies (private sector), small tea holders and entrepreneurs. In this study, only the tea plantations managed by plantation companies were considered. GHG emissions associated with the energy use were calculated for tea plantations, transport of green leaf, tea processing and bulk packaging. The identified energy sources and the related activities in each phase are as follows:

Table 1: Sources of energy and related activities in phases of life cycle

| Phase of the life cycle | Energy source | Related activities |

| Tea plantations | Purchased electricity | For estate office, bungalows and management activities |

| Diesel and Petrol | For land preparation and collection of tea leaves | |

| Transportation of green leaf | Diesel | For transport of green leaf to tea processing factories |

| Tea processing | Electricity | Operation of machinery |

| Diesel | For standby generator and transport of biomass | |

| Biomass | Generation of thermal energy |

Data related to the GHG emissions were collected for three consecutive years from 2012 (2012-2014) in the tea growing regions of High grown, Mid grown, Low grown and Uva region.

Sri Lanka has also gained recognition in manufacturing high quality natural rubber and value-added rubber products. In this study, the following types of rubber products were considered.

- Raw Rubber Products

- Crepe Rubber and Ribbed Smoked Sheet (RSS)

- Centrifuged/Concentrated Latex

- Technically Specialized Rubber (TSR)

- Value-Added Rubber Products

- Concentrated Latex Based products

- Dry Rubber Based products

Here, the GHG emissions associated with energy use at rubber plantations managed by plantation companies, transportation of rubber latex, processing of intermediate rubber products and manufacture of value-added rubber products were considered. The sources of energy used in each step and their related activities are as follows:

Table 2: Energy sources and related activities in phases of life cycle

| Phase of the life cycle | Energy source | Related activities |

| Rubber plantations | Diesel and Petrol | Tillage, collection of latex to a central tank and other transport |

| Electricity | Estate office and bungalows | |

| Transport of latex | Diesel | Transport of latex to raw rubber processing mills |

| Processing | Electricity | Used in the processing mills |

| Diesel | For the standby generator | |

| Biomass | For generation of thermal energy | |

| Value-added rubber product manufacturing | Electricity | Material handling activities |

| Diesel | Internal transport, standby generator, thermal energy generation, transport of biomass from sources to factories | |

| Fuel oil | Thermal energy generation | |

| Biomass | Thermal energy generation |

Data was collected for three consecutive years starting from 2012 (2012-2014) from a set of factories and plantations located in Kalutara, Colombo, Kegalle, Badulla, Galle and Ratnapura districts.

In this study, one metric ton of made tea was taken as the functional unit for tea sector while in rubber sector, one metric ton of dry rubber content (DRC) was used as the functional unit. GHGs considered in the calculations were CO2, CH4 and N2O. These emissions associated with the energy use of the considered process phases were calculated separately and converted into CO2 equivalent (CO2e) using Global Warming Potential (GWP) (i.e. heat absorbed by any GHG in the atmosphere, as a multiple of the heat that would be absorbed by the same mass of CO2. GWP for CO2 is 1) of each gas. Moreover, for plantations, soil carbon stocks and biomass carbon sequestration were considered as the main GHG sinks.

From the results obtained for tea plantations, following points can be highlighted.

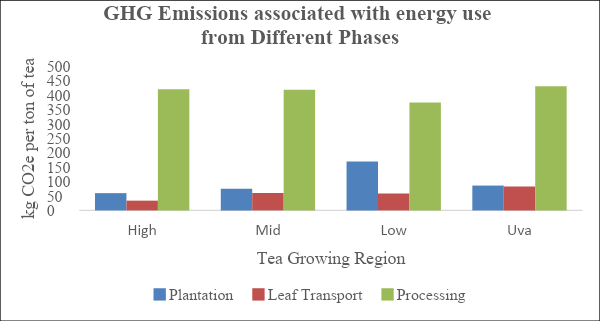

Figure 1: GHG Emissions associated with energy use from different phases in tea production

- Energy- related highest GHG emissions were recorded in green leaf processing phase.

- Among all the regions, the highest and lowest contributions for GHG emissions from energy usage were from High grown and Low grown regions respectively.

- Purchased electricity was the main energy source used and its contribution for GHG emissions was more than 63% of all emissions.

When considering the rubber plantations, GHG emissions associated with the value-added rubber product manufacturing was found to be higher than the values in rubber plantations and raw-rubber processing.

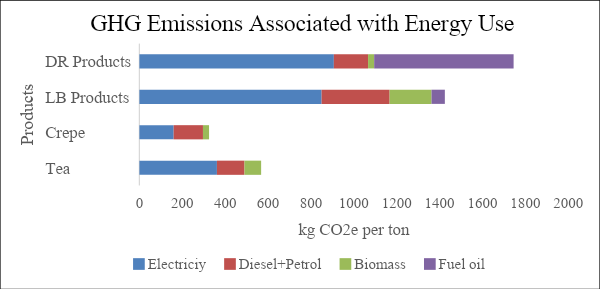

For comparison of the cradle-to-gate GHG emissions of the energy usage in tea and rubber sectors, all four types of products were selected: made tea, crepe rubber, latex based value-added products and dry rubber based value-added products. Out of both tea and rubber sectors, the highest GHG emissions were associated with value-added rubber products and purchased electricity was found to be the main contributory source for GHG emissions in both industries.

Figure 2: Comparison of GHG Emissions associated with energy use of tea and rubber production

One of the most important results revealed through this research was that the biomass and soil carbon sequestration rates are higher than the GHG emissions associated with the energy use of cradle-to-gate life cycle products in both sectors. This finding indicates the future opportunities to produce carbon neutral or carbon negative products in Sri Lanka which would definitely be a competitive advantage in high end market segments.

Furthermore, the researchers, Dr. Vidanagama and Prof. Lokupitiya suggest some mitigatory measures for the existing GHG emissions in these industries. They are,

- Energy efficiency improvement through energy management

- Technological improvement

- Increase in the share of renewable energy in the procedures

More importantly, this research provides the baseline for policy making related to climate change and involvement of manufacturers in,

- Existing (Clean Development Mechanism (CDM) and Sri Lanka Carbon Crediting Scheme (SLCCS)) and future carbon markets under Article 6 of the Paris Agreement

- Setting emission targets under Nationally Determined Contributions (NDCs)

- Developing an Emissions Trading System (ETS) for plantation sector

- Development of an internationally Transferred Mitigation Outcomes (ITMOs)

- Tapping internationally available climate financing opportunities to bring new climate smart technologies.

- Setting GHG emission benchmarks for tea and rubber products

- Establishing GHG emissions and mitigation actions monitoring, reporting and verification (MRV) system in the plantation sector.

In an era, where the whole world has concentrated on climate smart greener ways of consumption, these researchers could successfully come up with very significant findings on Sri Lankan export agriculture-based products which can positively affect the export economy of Sri Lanka and gain proper place in the international markets.

The researchers acknowledge the immense support given by the Department of Zoology and Environment Sciences of University of Colombo, National Research Council of Sri Lanka, Tea and Rubber Research Institutes and the management and staff members of tea and rubber plantations and factories for the successful accomplishment of this study.

Reference:

Vidanagama, J., & Lokupitiya, E. (2018). Energy usage and greenhouse gas emissions associated with tea and rubber manufacturing processes in Sri Lanka. Environmental Development, 26, 43–54. https://doi.org/10.1016/j.envdev.2018.03.006

For further information- https://www.sundaytimes.lk/211003/news/first-ever-study-to-gauge-the-carbon-footprint-from-energy-use-in-tea-production-457186.html

Written by: Vihanga Lakshani Amarakoon